53xx BDA Universal Fine Wire & Die Bonder Specifications

|

Concept |

DC motor driven

linear Z axis

Single board PC

with Windows®

operating system

Menu controlled

teach

User interface

via colour screen and shuttle-wheel with push-button

|

Bondtec 53xx BDA Datasheet

Bondtec 53xx BDA Datasheet

53xx Video

|

|

Wire types |

Ball-bonding: Gold wire, 17.5 - 50 μM on 2”

spool (½” Spool optional)

Wedge bonding: Aluminium or Gold wire, 17.5 - 75

μM. Ribbon, 30 x 12.5µM - 250 x 25 μM

|

|

Bondhead |

Ball bonding or Wedge bonding for fine wire

Capillaries: 9 - 16mm length

Wedges: 0.750" or 1” length

Bond force: programmable, 5 - 150g Voice-coil

bond force system

Contactless electronic touchdown sensor

Programmable

Ultrasonic system: 60 kHz or 100 kHz, switchable

|

|

Display |

6.5” TFT Colour

Display. 640 x 480 Pixel (VGA)

|

|

Working area |

Bondhead linear Z

travel: 60 mm. Step precision: 1µM

Programmable

linear Y axis: 8mm. Step precision 2µM

X&Y Manipulator;

18 x 18 mm Movement ration; 7:1

|

|

Workholder |

Digitally

controlled heated stage

Standard Ø - 80

mm for samples to 2" x 2", mechanical clamping

4" x 4" &

95 mm optional, also with vacuum

|

|

Control modes |

Manual,

semi-automatic

Program line step

for testing via Shuttle-wheel

|

|

Loop types |

Standard

rectangular, Reverse, Stitch, Programmable

|

|

Dimensions |

Height: 400mm,

Width: 630mm, Depth: 580mm. Weight approx. 40kg

|

|

|

|

|

Programme Storage |

Internal Hard

Disc Drive

|

|

|

|

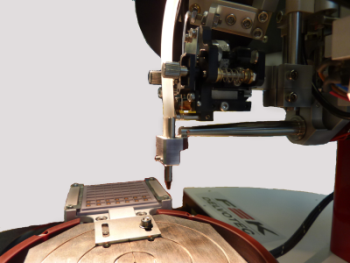

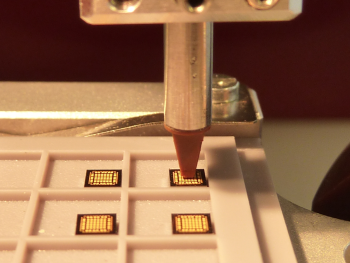

The 53xx BDA is now capable of

DIE-Bonding

Our popular manual

wire bonder 53xx BDA was already a marvel of

versatility, being extremely simple to convert

between wedge and ball bonding. Now it adds a

third functionality; the 53xx BDA is now capable

of DIE bonding.

Only

a minimum of changes in hardware and software

are required. In place of the wire bond tool an

adapter is attached directly to the transducer

in order to mount standard tools for chip

bonding, so-called DIE collets. These are

available from a variety of suppliers in

different shank diameters, all of which fit into

the three mounting holes. The chips are supplied

in waffle packs which can be mounted right next

to the standard bonding chuck. Only

a minimum of changes in hardware and software

are required. In place of the wire bond tool an

adapter is attached directly to the transducer

in order to mount standard tools for chip

bonding, so-called DIE collets. These are

available from a variety of suppliers in

different shank diameters, all of which fit into

the three mounting holes. The chips are supplied

in waffle packs which can be mounted right next

to the standard bonding chuck.

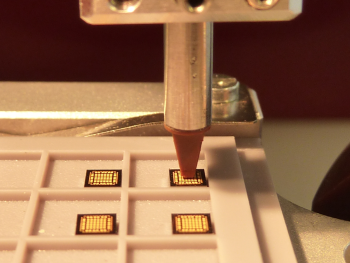

A

special software version makes DIE-bonding on

the 53xx BDA just as straightforward and

comfortable as wire bonding. Step one is to

shift the bonding chuck sideways so that the

waffle pack with the desired DIE comes to sit

just under the DIE collet. Just like for wire

bonding, the user does a fine adjustment under

the microscope with the manipulator. Step two is

to lower the bond tool onto the chip where a

touchdown signal is registered and the vacuum is

switched on automatically which sucks the chip

to the DIE collet. Using this touchdown

procedure makes sure that the chip is touched

with a defined force – a particularly important

feature for sensitive or thin DIE. A

special software version makes DIE-bonding on

the 53xx BDA just as straightforward and

comfortable as wire bonding. Step one is to

shift the bonding chuck sideways so that the

waffle pack with the desired DIE comes to sit

just under the DIE collet. Just like for wire

bonding, the user does a fine adjustment under

the microscope with the manipulator. Step two is

to lower the bond tool onto the chip where a

touchdown signal is registered and the vacuum is

switched on automatically which sucks the chip

to the DIE collet. Using this touchdown

procedure makes sure that the chip is touched

with a defined force – a particularly important

feature for sensitive or thin DIE.

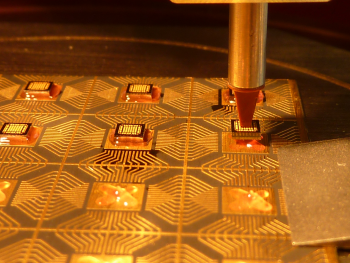

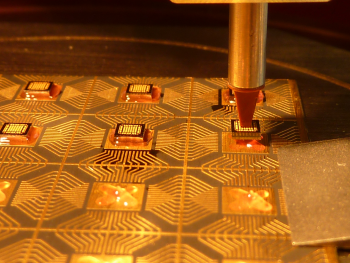

Step

three takes place after the bond tool with the

chip has moved up: the circuit is shifted back

under the bond tool and adjusted precisely,

still using the microscope. The final step

consists of automatic, motorized lowering of the

chip, again under touchdown control, and pushing

the chip into the prepared adhesive bed under a

defined and programmable bond force and bond

time. At this crucial process step, the 53xx BDA

is actually superior to many fully automatic DIE

bonders because it can apply a defined bond

force and time and therefore make sure that even

fragile chips are bonded delicately but over the

full area. This works even when the heights of

the components vary, thanks to the touchdown

feature. Step

three takes place after the bond tool with the

chip has moved up: the circuit is shifted back

under the bond tool and adjusted precisely,

still using the microscope. The final step

consists of automatic, motorized lowering of the

chip, again under touchdown control, and pushing

the chip into the prepared adhesive bed under a

defined and programmable bond force and bond

time. At this crucial process step, the 53xx BDA

is actually superior to many fully automatic DIE

bonders because it can apply a defined bond

force and time and therefore make sure that even

fragile chips are bonded delicately but over the

full area. This works even when the heights of

the components vary, thanks to the touchdown

feature.

Once the chip is attached, the vacuum is turned

off automatically and the bond tool moves to the

programmed height under motor control. The

operator can immediately inspect the chip

placement and the glue fillet.

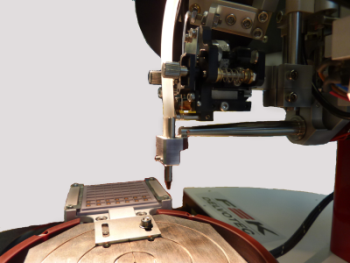

A particularly attractive aspect of the 53xx BDA

is that the bonder can be switched back to wire

bonding within minutes. By the time the circuit

with the mounted DIE comes out of the curing

oven, the bonder is all ready to go for the

subsequent wire bonding step.

Another special goody: the DIE bond attachment

fits all newer 53xx BDA wire bonders. This makes

it a most welcome add-on for sample building or

small-volume production, all the more so as DIE

bonding is not only cost-effective but even

extremely delicate and, for a manual bonder,

done at high precision. A video is available on

our internet site. |

|

|

53xx BDA Manual Universal Fine Wire

& Die Bonder

53xx BDA Manual Universal Fine Wire

& Die Bonder

Only

a minimum of changes in hardware and software

are required. In place of the wire bond tool an

adapter is attached directly to the transducer

in order to mount standard tools for chip

bonding, so-called DIE collets. These are

available from a variety of suppliers in

different shank diameters, all of which fit into

the three mounting holes. The chips are supplied

in waffle packs which can be mounted right next

to the standard bonding chuck.

Only

a minimum of changes in hardware and software

are required. In place of the wire bond tool an

adapter is attached directly to the transducer

in order to mount standard tools for chip

bonding, so-called DIE collets. These are

available from a variety of suppliers in

different shank diameters, all of which fit into

the three mounting holes. The chips are supplied

in waffle packs which can be mounted right next

to the standard bonding chuck. A

special software version makes DIE-bonding on

the 53xx BDA just as straightforward and

comfortable as wire bonding. Step one is to

shift the bonding chuck sideways so that the

waffle pack with the desired DIE comes to sit

just under the DIE collet. Just like for wire

bonding, the user does a fine adjustment under

the microscope with the manipulator. Step two is

to lower the bond tool onto the chip where a

touchdown signal is registered and the vacuum is

switched on automatically which sucks the chip

to the DIE collet. Using this touchdown

procedure makes sure that the chip is touched

with a defined force – a particularly important

feature for sensitive or thin DIE.

A

special software version makes DIE-bonding on

the 53xx BDA just as straightforward and

comfortable as wire bonding. Step one is to

shift the bonding chuck sideways so that the

waffle pack with the desired DIE comes to sit

just under the DIE collet. Just like for wire

bonding, the user does a fine adjustment under

the microscope with the manipulator. Step two is

to lower the bond tool onto the chip where a

touchdown signal is registered and the vacuum is

switched on automatically which sucks the chip

to the DIE collet. Using this touchdown

procedure makes sure that the chip is touched

with a defined force – a particularly important

feature for sensitive or thin DIE. Step

three takes place after the bond tool with the

chip has moved up: the circuit is shifted back

under the bond tool and adjusted precisely,

still using the microscope. The final step

consists of automatic, motorized lowering of the

chip, again under touchdown control, and pushing

the chip into the prepared adhesive bed under a

defined and programmable bond force and bond

time. At this crucial process step, the 53xx BDA

is actually superior to many fully automatic DIE

bonders because it can apply a defined bond

force and time and therefore make sure that even

fragile chips are bonded delicately but over the

full area. This works even when the heights of

the components vary, thanks to the touchdown

feature.

Step

three takes place after the bond tool with the

chip has moved up: the circuit is shifted back

under the bond tool and adjusted precisely,

still using the microscope. The final step

consists of automatic, motorized lowering of the

chip, again under touchdown control, and pushing

the chip into the prepared adhesive bed under a

defined and programmable bond force and bond

time. At this crucial process step, the 53xx BDA

is actually superior to many fully automatic DIE

bonders because it can apply a defined bond

force and time and therefore make sure that even

fragile chips are bonded delicately but over the

full area. This works even when the heights of

the components vary, thanks to the touchdown

feature.